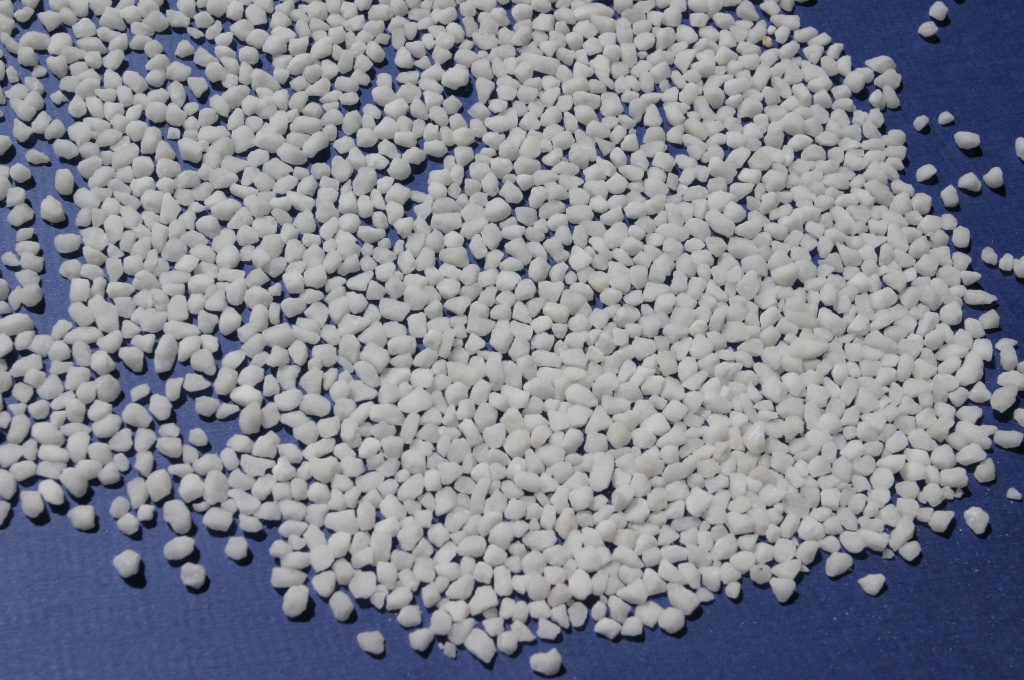

The constantly growing demand from consumers for the highest quality halurgical potassium chloride fuels the production development, its extensive modernization and overall technical upgrade.

The new regulated vacuum-crystallization unit with the capacity of 1.5 mln tons per year has been put into operation; the equipment renovation and modernization of all the process stages is in progress. New products with various additives are constantly being developed according to consumers' requirements.

PROCESSING PLANT OF PU 4 PRODUCES AND SUPPLIES THE FOLLOWING PRODUCTS:

-

Potassium chloride standard

-

Potassium chloride granular

-

Potassium chloride fine granular

-

Potassium chloride granular (technical, dedusted)

-

Sodium chloride technical (Grade B)

-

Mineral concentrate – halite (Grade B)

DIRECTOR OF PU 4SERGEY PATIYUK

|

PERSONAL RECEPTION OF CITIZENS:1st and 3rd Monday of each monthPre-appointment call on a day of reception Tel.: 00 375 174 29 41 47 |

HISTORY

The idea to build the 4th Soligorsk Potash Plant, different from existing plants of this kind, belonged to Leonid Kostandov, who was then the minister of the chemical industry. In doing so, he wanted to solve a number of problems: first, the flotation method of beneficiation did not allow further use of salt tailings piles and the food salt that could be produced from wastes was required, and second, the production of chloride-free potassium fertilizers (potassium sulphate) was needed.

1971 – start of works on the creation of a new mining and chemical facility – the 4th Soligorsk Potash Plant.

30 August 1975 – a commercial bed of sylvinite at a depth of 593 metres was tapped in the first shaft.

15 December 1978 – commissioning of the mine.

15 January 1979 – a team of the processing plant produced the first potassium concentrate. Production began with the output of 95% fine-crystalline potassium chloride.

2000-2005 – a number of facilities designed by JSC Belgorkhimprom underwent refitting and technical upgrades, which allowed to increase production capacities of the Production Unit.

Since 2001 – a sustainable and low-cost method of production of 98% of products, both fine-grained and coarse-grained, was launched.

October 2003 – commissioning of the gas pipeline of PU 1 - PU 4 made it possible to operate completely on the green fuel – natural gas – without using heavy fuel oil.

2015 – start-up of the Membrane Electrolysis Shop (Chemical Plant). More details>>>>