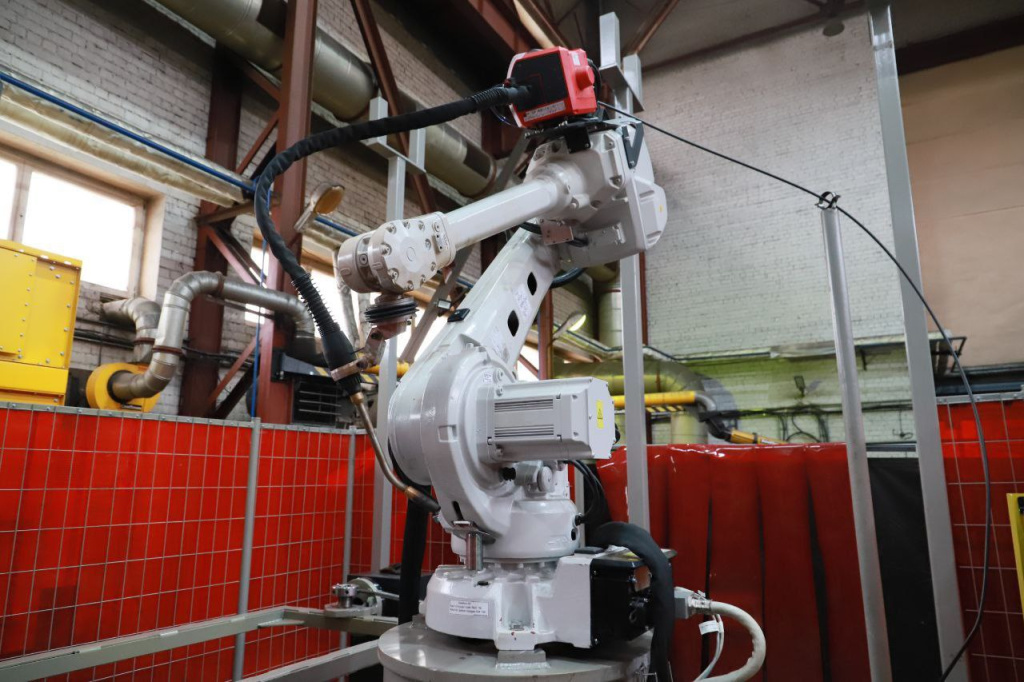

One of the acquisitions to improve the production potential was a welding robotic centre designed for the manufacture of scraper conveyor pans at the Repair and Mechanical Shop.

A 2.5 tonne capacity rotary bottom-pour ladle was also purchased for the foundry section of the Repair and Mechanical Shop. The new equipment will help to eliminate slag inclusions in castings made of high alloys, which affect the quality of castings. At the moment the foundry section is working out the technology of steel casting with the use of the new equipment. If necessary, the ladle of increased capacity will allow to accommodate the total melt volume of all available melting furnaces of the site. Thus, the range of products meeting all technical requirements will be increased.

At the moment the specialists of the production section No. 4 of the Repair and Mechanical Shop have completed the installation of the centre and have moved on to the next stage - training of the shop personnel.

← Back to the list